Science popularization and innovative design of professional application fields for board to board connectors

The widespread application of board to board connectors has emerged against the backdrop of electronic devices continuously moving towards miniaturization, integration, and high-speed development. The trend of domestic substitution of board to board connectors is becoming increasingly evident! This trend not only reflects changes in market demand, but also embodies the comprehensive role of technological progress and policy support. With the popularization and acceleration of electronic products, the requirements for connections between circuit boards are also increasing. Science popularization and innovative design of professional application fields for board to board connectors

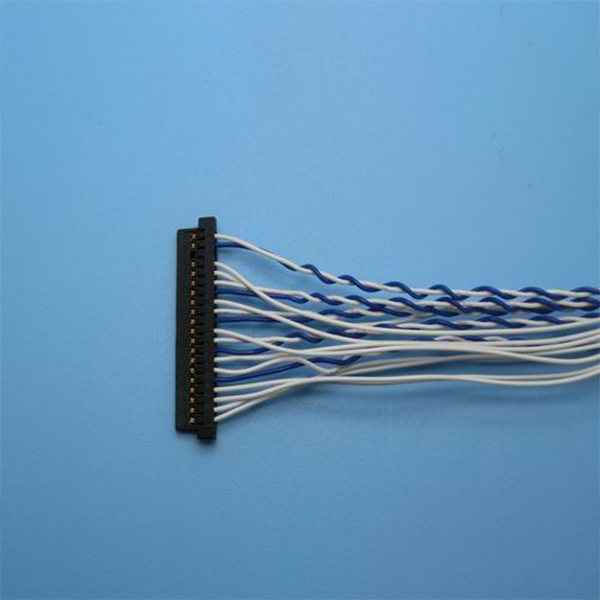

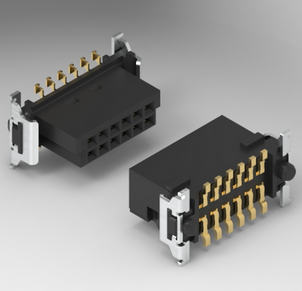

Segmented explanation of the application areas of board to board connectors:The application of board to board connectors is equally widespread. With the development of the Internet, the data center has become an important infrastructure. Board to board connectors are mainly used in data centers to connect servers, storage devices, network equipment, etc., achieving high-speed transmission and exchange of data. Due to the extremely high requirements for data transmission speed and stability in data centers, board to board connectors play a crucial role here. The field of medical instruments is also one of the important application areas of board to board connectors. With the development of medical technology, more and more medical instruments have entered households. Board to board connectors are mainly used in medical instruments to connect components such as power supply, signal transmission, and data storage, improving the safety and reliability of the instrument. For example, in an electrocardiograph, board to board connectors ensure accurate transmission and storage of electrocardiogram signals, providing doctors with accurate diagnostic basis. In addition, in remote medical systems, board to board connectors also play a key role, such as video calls, data transmission, etc., allowing patients to receive professional medical services at home, reducing medical and time costs. As an indispensable core component in modern electronic devices, board to board connectors will greatly change people's way of life and work with the promotion of 5G technology. In 5G communication systems, board to board connectors are mainly used to connect devices such as base stations, antennas, and terminals, achieving high-speed wireless signal transmission. The 5G communication system has extremely high requirements for the performance and reliability of connectors, as any minor malfunction can lead to communication interruption or data loss. Board to board connectors, with their high reliability and stability, ensure the normal operation of 5G communication systems and the accuracy of data transmission. With the rapid development of industrial automation, robots have been widely used in various production fields. Board to board connectors are mainly used in robots to connect components such as sensors, actuators, and control boards, achieving various functions of the robot. For example, in industrial robots, board to board connectors ensure accurate connection and communication between sensors and actuators, enabling the robot to perform precise operations according to preset programs. The stability and reliability of this connection method are of great significance for improving production efficiency and product quality. Precautions for using board to board connectors:Board to board connectors are divided into single slot, double slot, and side plug types, with the main characteristics of fast transmission speed, wide application range, and flexible installation. Board to board connectors need to pay more attention to details in application, otherwise it is easy to cause damage and affect the use of the product. Board to board connectors are a type of connector that generates heat during signal transmission after each insertion, resulting in loss and gradually weakening the performance of the connector. When the number of insertions and removals of board to board connectors reaches a certain level, the connector terminals will also wear out. If not maintained in a timely manner, it can lead to board to board connector failures. Qualification and Certification of Board to Board Connector Production and Wholesale SuppliersIndustry certification: Products must pass UL, CE, RoHS and other certifications to comply with international standards. Technical support: Suppliers are required to provide comprehensive services such as selection guidance, sample testing, and failure analysis. The localization of board to board connectors not only helps to reduce costs, but also promotes the independent and controllable development of the entire electronic industry chain, laying a solid foundation for the rise of Chinese manufacturing. Friendly reminder, when selecting board to board connectors, a comprehensive evaluation should be conducted from multiple dimensions such as technical parameters, application scenarios, and supplier qualifications to ensure that the product meets system requirements.